Belt Conveyors

Fabric, Rubber and PVC Belt Conveyors

Australis offers a range of fabric, rubber and PVC belt conveyors to suit virtually any application. We have been locally manufacturing belt conveyors since 1983 and have supplied thousands of conveyors for a huge range of applications and industries. Our conveyors are trusted by some of Australia’s largest manufacturers to reliably convey their products. We manufacture our Belt Conveyors to order based on our smart, standard designs. However all of belt conveyors are also fully customisable – we can manufacture any length, width or height conveyor to suit your space or application (note mechanical limitations apply). Our belt conveyors are suitable for fresh or packaged food, beverages, horticultural, warehousing and logistics, dispatch, mail and package sorting, health and pharmaceutical, medical devices, automotive, aerospace, general manufacturing and industrial applications.

All of our Belt Conveyors are Australian made by Australis on-site at our Sydney premises.

We offer a complete range of belt conveyors including:

- Custom length, width and height

- Lightweight or Heavy duty

- Stainless steel, mild steel or aluminium construction

- High speed, low speed and variable speed

- Regular, smooth, rough-top, cleated and wavy wall belts

- Incline and decline conveyors

- Clean in Place (CIP)

- Standard Food grade

- Hygienic grade

- Medical/ Pharmaceutical grade

- Warehousing and Distribution centres

- Mail sorting

- Waste management

- Specialist Trough Conveyors

Click on the Tab above to Learn More about our 30, 50 and 95 Series Aluminium Belt Conveyors

Our fabric, rubber and PVC belt conveyor bodies and leg-sets are manufactured from aluminium profile, mild steel or stainless steel depending on the application and operating environment. Our belt conveyors can be easily designed to meet food-grade and pharmaceutical standards (HACCP or TGA).

We offer a variety of fabric belt or rubber belt types to suit your product mix. Our Belt Conveyors can be supplied with food grade (anti-microbial), rough top, heavy duty, multi-ply or cleated belts and everything in between. Australis has a range of standard belt conveyor designs that can be manufactured quickly and adapted to suit your requirements. We offer options for Mini Belt Conveyors, Ultra-Light, Light-Duty, Medium and Heavy Duty Belt Conveyors.

Belt Conveyors for virtually any product

Our locally manufactured belt conveyors are suitable for virtually any product or package type, including:

- Food processing

- Fruit sorting and packing

- Chicken and Meat products

- Grain and cereals

- Bread and bakery products

- Large and small cartons or boxes

- Plastic wrapped or shrink wrapped products

- Bags, sachets or pouches

- Bottles, cans and jars (including plastic, metal or glass)

- Tubs and small drums

- Loose or Bulk materials (eg trough conveyors)

- Automotive or Aerospace components

- Computer/ IT components

- Incline belt conveyors or decline belt conveyors

- Clean In Place (CIP) belt conveyor systems

- Standard Food grade belt conveyors (including wash down and anti-microbial belts)

- Hygienic standard, food grade conveyors

- Pharmaceutical, health or medical device applications

- Warehouse and dispatch areas

- Mail sorting or Parcel sorting

- Product picking or sorting areas

- Waste sorting/ waste management and bio-solid applications

- Horticultural and Agricultural products

- Trough conveyors for bulk or loose product such as sand, minerals, grains or cereals

Customised Belt Conveyors

In addition to our standard, belt conveyor modules, Australis offer fully customised belt conveyors. Customised conveyors are designed to precisely match your product, load requirements, through-puts, health and safety requirements, budget or production environment. Our belt conveyors can be manufactured with options including:

- Mild steel (painted or galvanised), stainless steel or aluminium profile construction

- Virtually any width or length

- Fully or semi automated controls

- Line control

- Variable speed controls

- Energy saving drives

- A range of belt types (eg fabric belts, rubber belts, PVC belts, cleated belts and more)

- Belt over rollers

- Wash down standards

- Food-grade standards

- Integration with other conveyors and equipment, including data sharing (internet of things)

- Integration to existing capital equipment – simply replace the belt conveyor, not your machine

- Belt conveyor machine guarding

Conveyor Design

Australis provides customised belt conveyor systems. Our engineers will help you with the process of belt conveyor design. Our team of engineers will assist you to:

- determine the most effective conveyor layout

- calculate the belt loading and help select the correct motor and drive

- ensure you achieve the correct belt speed to meet your throughput requirements

- select the right belt type for your application

- ensure the belt is tensioned correctly

- ensure the belt tracks correctly

- implement line control and other industrial automation

- integrate your conveyor or conveyor system with other equipment

- service and maintain your conveyors

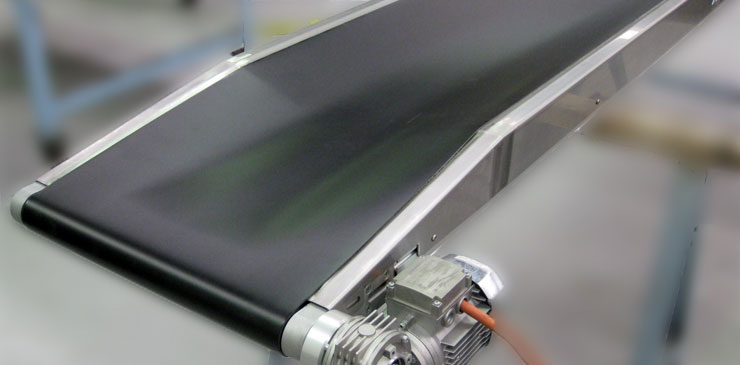

Series 30 Belt Conveyors

Series 30 Conveyors are best suited for ultra light and lightweight products (up to 15kg/m) or where there is restricted height for installation. The Series 30 belt conveyor offers a slimline body height of only 40mm with head and idler rollers only 30mm. This allows the Series 30 Belt Conveyor to fit into tight spaces, which makes an ideal solution for installing inside existing machines or anywhere space is at a premium. If you are looking for a mini belt conveyor, this is the best option.

Series 30 Conveyors are best suited for ultra light and lightweight products (up to 15kg/m) or where there is restricted height for installation. The Series 30 belt conveyor offers a slimline body height of only 40mm with head and idler rollers only 30mm. This allows the Series 30 Belt Conveyor to fit into tight spaces, which makes an ideal solution for installing inside existing machines or anywhere space is at a premium. If you are looking for a mini belt conveyor, this is the best option.

Most commonly requested in Aluminium Profile, but also available in Painted Mild or Stainless Steel as an option. Standard Components mean the Series 30 Belt Conveyors are Easily and Quickly Customised to suit your products or available floor space.

Specifications:

Belt speed: 2m/min to 30m/min

Motor Rating: 0.12kW to 0.25 kW

Available Lengths: 350mm to 3,000mm

Available Widths: 100mm to 400mm

Max. belt loading: 15 kg/m

Belt types available:

- Rough top belt

- Flat top belt (PVC, Silicon, Chemical Resistant)

- Food approved belts

- Special belts (for custom applications)

Drive position available:

- Front end direct drive, left

- Front end direct drive, right

- Centre drive

Series 50 Belt Conveyors

The Series 50 Conveyors are best suited for light to medium weight products up to 30kg/m. The Series 50 Belt Conveyor offers a slimline body height of only 45mm with head and idler rollers of 50mm. The Series 50 is a flexible conveyor system which can be used for horizontal conveying and elevating products. A robust yet economical elevator conveyor or incline conveyor can be achieved by adding cleats to a standard belt.

The Series 50 Conveyors are best suited for light to medium weight products up to 30kg/m. The Series 50 Belt Conveyor offers a slimline body height of only 45mm with head and idler rollers of 50mm. The Series 50 is a flexible conveyor system which can be used for horizontal conveying and elevating products. A robust yet economical elevator conveyor or incline conveyor can be achieved by adding cleats to a standard belt.

Most commonly ordered in Aluminium Profile, but also available in Painted Mild or Stainless Steel; as an option it is also available as an incline or decline conveyor. The Aluminium variants of this conveyor are virtually modular and so can be easily and quickly customised to suit a specific application or product.

Specifications:

Belt speed: 2m/min to 40m/min

Motor Rating: 0.12 kW to 0.37 kW

Available Lengths: 350mm to 6,000mm

Available Widths: 100mm to 600mm

Max. belt loading: 30 kg/m

Belt types available:

- Rough top belt

- Flat top belt

- Food approved belts

- Cleated belts

- Special belt (for custom applications)

Drive position available:

- Front end direct drive, left

- Front end direct drive, right

Series 95 Belt Conveyors

The Series 95 Conveyors are best suited for medium-heavy weight products with a maximum belt loading of 70kg/m. Aluminium profile Series 95 Belt Conveyors are highly modular and can be customised to fit into your available floor space or to suit a specific product. The Series 95 offers a robust 90mm high side frame with head and idler rollers of 95mm. The Series 95 can be used for horizontal conveying and elevating products. A robust yet economical elevator can be achieved by adding cleats to a standard belt.

The Series 95 Conveyors are best suited for medium-heavy weight products with a maximum belt loading of 70kg/m. Aluminium profile Series 95 Belt Conveyors are highly modular and can be customised to fit into your available floor space or to suit a specific product. The Series 95 offers a robust 90mm high side frame with head and idler rollers of 95mm. The Series 95 can be used for horizontal conveying and elevating products. A robust yet economical elevator can be achieved by adding cleats to a standard belt.

Most commonly ordered in Aluminium Profile, but also available in Painted Mild or Stainless Steel; as an option it is also available as an incline or decline conveyor.

Specifications:

Belt speed: 2m/min to 50m/min

Motor Rating: 0.12kW to 0.55 kW

Available Lengths: 500mm to 12,000mm

Available Widths: 200mm to 1,000mm

Max. belt loading: 70 kg/m

Belt types available:

- Rough top belt

- Flat top belt

- Cleated belt

- Special belt (for custom applications)

Drive position available:

- Front end direct drive, left

- Front end direct drive, right

- Centre drive

Click on the case study below to view

Find out more by reading the following Case Studies of our projects that feature belt conveyors:

AFS – Conveyor system for architectural wall panels

Colorpack – Conveyor system for cardboard packaging (featured in the video in the next tab)

Donaldson Filters – Conveyor system for automotive filters

CHEP – Heavy duty belt conveyors for pallet inspection system

The following video highlights a range of conveyors manufactured by Australis Engineering – including several belt conveyors

RELATED PRODUCTS

PREVIOUS CLIENTS