Conveyor Systems

Conveyor Systems

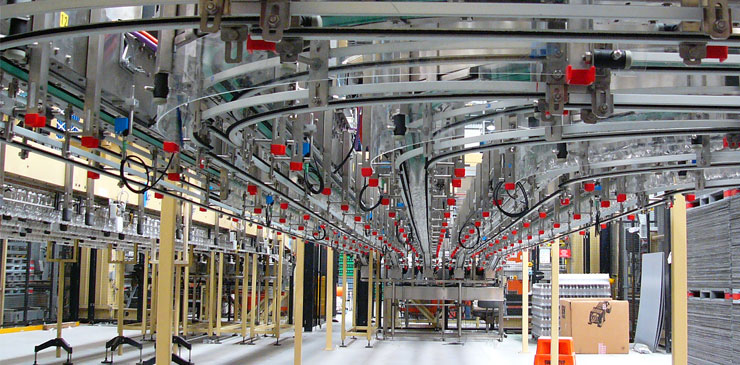

Australis has been in the business of designing and manufacturing conveyor systems since 1983. Conveyor systems are one of our core capabilities and we bring you an enviable track-record of providing successful conveying solutions to most of Australia’s largest manufacturing brands in the FMCG, Medical, Pharmaceutical, Automotive, Industrial, Hazardous Substance, Government and Building Products sectors. We have supplied our conveyor systems to some of Australia’s largest food, beverage and pharmaceutical manufacturers – and we have core capabilities in conveying bottle, jars, cans and cartons, however over our 30+ year history we have conveyed a huge range of diverse products from tiny, fragile glass vials and coin blanks to train wheels and construction scale wall panels. Our conveyor systems are based on standardised. modular designs but are customised to suit your layout, product characteristics, floor space, safety requirements, delivery time frame and of course your budget. We can provide integration with your existing capital equipment or other conveyor systems, or we can design an entire turnkey materials handling solution incorporating capital equipment, conveyors and with full line control and automation.

Whether your budget is $5,000 or $20 million, Australis have the track-record and capabilities to deliver on your conveyor system requirements.

Australis Engineering’s team of qualified mechanical and automation engineers can help to solve your conveying problems. We have SolidWorks 3D CAD capabilities and are able to tailor our standard conveyor range to meet your requirements. With ISO9001:2008 Quality Management and ISO31000:2008 Risk Management certifications, you can also have peace of mind that our comprehensive internal design, quality assurance and manufacturing processes will help us deliver your project with the minimum of risk.

Conveyors

Our can design and manufacture a wide range of conveyor types to handle boxes or cartons, bags, bottles, jars, cans, satchets, bulk product, individual product, pallets, drums and just about any other product you can imagine. Options include:

- Belt conveyors

- Slat chain conveyors

- Roller conveyors

- Pallet conveyors

- Modular belt conveyors

- Air conveyors

- Incline conveyors

- Single filer conveyors

- Lane diverters

- Conveyor Guide Rail Systems

Or any combination of the above to achieve your project requirements

Conveyors – Domestic and Export Success

Clients are motivated by many different ‘hot-button’ issues. Whether your challenge is to improve manufacturing efficiency and output, reduce OHS concerns and lost-time-injuries or simply wanting to modernise your manufacturing, our enthusiasm to provide an innovative, tailor made system ensures that as our client, you will receive the best for business solution that fits within your budget. Australis Engineering’s reputation for providing innovative, tailored solutions is built on a strong track-record of project delivery and includes:

- Circulating coin materials handling and warehousing system inclusive of robotic drum handling and robotic pick and place, at the Royal Australian Mint, Canberra

- Materials handling system to decant highly toxic waste material from existing steel drums to new steel drums for Orica Australia Pty Ltd, Sydney

- Diverter conveyor table, pallet turntables and product conveyors, De Bortoli Wines, Bilbul NSW

- Pallet inspection and conveying system, Drake International (Owens-Illinois Glass), Sydney, Brisbane, Melbourne and Adelaide

- Complete air conveyor systems for PET bottle conveying, Coca-Cola, Sydney

- Bottle conveyors including spiral conveyors, Cerebos, Sydney

- Multi-pallet position linear palletiser with ‘smart’ infeed conveyors and product elevators for sausage casings, Devro Australia, Bathurst, NSW

- Automated wall panel conveying system with integrated oven and panel stacker, Architectural Framing Systems, Goulburn, NSW

- Conveyor system in a sub-zero environment for blood product at the Australian Red Cross Blood Bank, in Sydney, Melbourne and Perth

- Multi-axis conveyor system for a confectionery product, MARS Chocolate, Ballarat VIC

- Dissolved Acetylene Gases conveying system for BOC Gases Ltd, Sydney

- Palletising in feed conveyor systems, Sunrice, Leeton NSW

- Radioactive waste material conveying system, ANSTO, Sydney

- Tailored air conveyor system for PET bottles, VISY PET, Vietnam and Coca-Cola, Fiji

- Food-grade, decline belt conveyors, Taylor North & Associates, USA

- Air conveying system for beverage manufacturing plant, Heineken International, New Caledonia

- Special purpose indexing conveyor for Apollo Batteries, USA

- Conveyor system with continuous carton elevators for cardboard box production, Colorpak, Sydney

- Glass bottle conveying system, 4 Pines Brewery, Sydney

Contact Us to ask how we can help improve your manufacturing efficiency with a fully integrated and automated conveyor system

Contact UsClick on the case study below to view

Find out more about our extensive conveyor system expertise by reading the following Case Studies:

Royal Australian Mint – Circulating coin manufacturing line and warehousing system

BOC Ltd – Acetylene Bottle Conveyor system

Australian Red Cross Blood Bank – Sub Zero Freezer Conveyor Systems

Colorpak – Conveyor system for cardboard boxes

The following video demonstrates the Turnkey materials handling system at the Royal Australian Mint:

Conveyor Systems

Click here on on the brochure to learn more about our Conveyor Systems.

Materials Handling Capabilities

Click here or on the brochure image to view more information on our Materials Handling and Robotics capabilities.

Click here or on the brochure image to view more information on our Materials Handling and Robotics capabilities.

RELATED PRODUCTS

PREVIOUS CLIENTS