Customised Materials Handling Equipment

Fully Customised Machinery

Why would you need customised machinery? If you can’t find an “off-the-shelf” solution, ask yourself the following questions:

- Is Your Product Unique?

- Is it Heavy, Ultra Light, Fragile, Sticky, Slippery or Oddly Shaped?

- Is Your Production Process Unique or Complex?

- I have a Problem with no solution?

- I have a Solution but the Machinery doesn’t exist?

If you answered ‘yes’ to one or more of the above questions, there is a good chance we can help by designing a fully tailored, special purpose machine to suit your application.

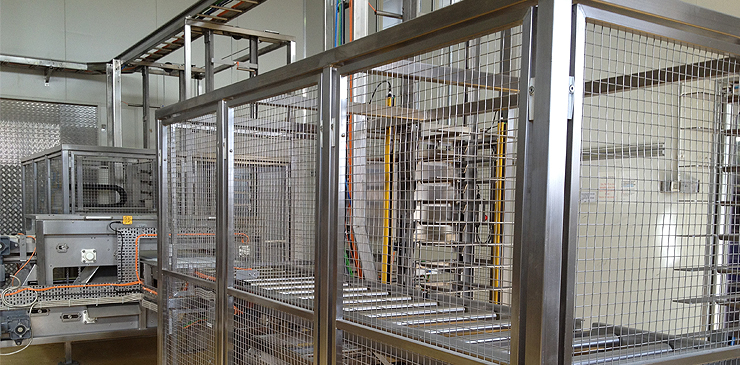

Fully Customised Materials Handling Equipment

Talk to Australis about a Fully Customised Materials Handling Equipment solutions – we have a proven track record in solving complex problems for our Clients by designing and manufacturing a customised, 1-off machinery to cater for your materials handling requirements. We have designed and manufactured machinery solutions for a wide range of products from a diverse range of industries – from light weight to heavy products, fragile to robust products, products requiring special manufacturing processes or products that are oddly shaped and therefore difficult to handle.

We have a wealth of experience to help solve your customised materials handling equipment challenges!

We offer Proven Materials Handling Machinery Design and Manufacture

If you need a fully customised materials handling equipment solution, Australis will:

- Conduct an R&D process

- Offer Proof of Concept Designs for the machinery

- Provide Pre-Manufacture Design Drawings for your Sign-Off

- Build a Proto-Type Machine

- Project Manage the Process

- Manufacture and Commission the agreed machinery solution

- Implement a Turnkey Materials Handling Equipment Solution

Our Team of Engineers and Tradespeople offer:

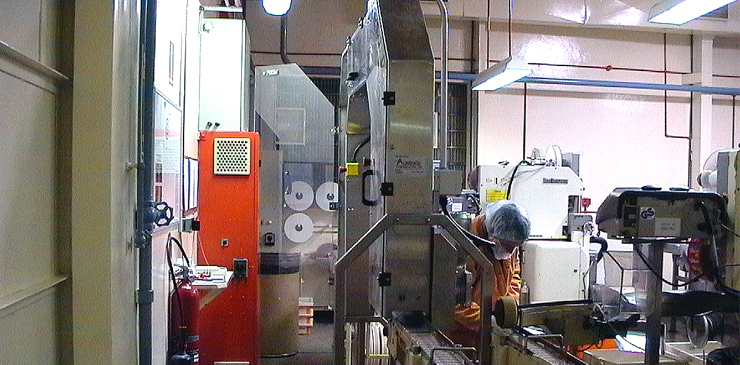

- Designs that meet Australian Standards including where required the stringent HACCP standards for food safety and pharmaceuticals

- In-house Mechanical, Electrical and Mechatronic Engineering expertise

- 3D CAD designs

- Processes that are ISO9001 and ISO31000 certified

- Experience across a wide range of industry sectors – meaning we bring our diverse experience to solving your bespoke machinery challenges

- Peace of Mind from a Proven Record in successful project delivery, including multi-million dollar contracts

Engineering Design Consultancy

Australis Engineering has a proven record in providing engineering design consultancy services for any mechanical or automation related engineering projects. With core strengths in the food, beverage, pharmaceutical, health, chemical and hazardous substance industry sectors, and using state of the art 3D CAD software, our team of mechanical and mechatronics engineers are well placed to assist you with your engineering concept and design requirements. Our capabilities include:

- Engineering concept design

- Engineering detailed design

- Tender preparation

- Engineering trouble-shooting

- Safety assessments (machine safety)

Australis has provided our engineering consultancy or R&D services to a diverse range of Clients including:

- AusReo

- BOC Ltd (Linde Group)

- KPMG

- Australian Nuclear Technology and Science Organisation (ANSTO)

- Orica Australia

- Dywidag Systems International

- Australian Red Cross Blood Bank Service

- Sauer’s Bakehouse

- Alto Manufacturing

- ABC Tissues

- Casella Wines

- Thales

- Royal Australian Mint

- Wrigley’s (MARS)

- Architectural Framing Services

- Tru Blu Beverages

- and many more …

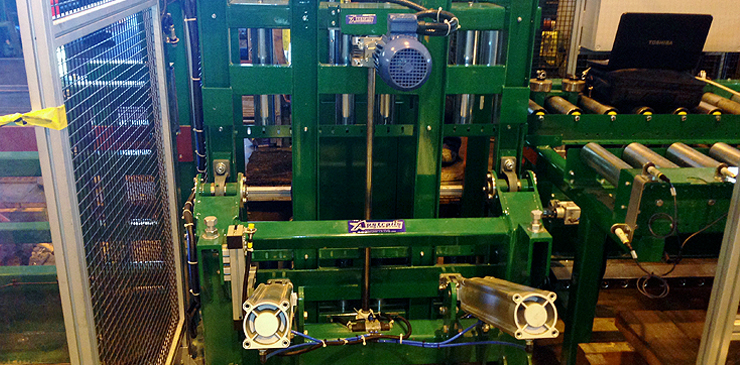

In House Manufacturing Capabilities

Australis Engineering has a comprehensive manufacturing and fabrication facility at its headquarters in Sydney. With a team of highly qualified tradespeople and technicians, we have the ability to manufacture any of our mechanical designs in-house. Whether your business is handling something as small and delicate as a glass vial, mushroom or coin to heavy duty items up to around 6 tonne – Australis has the capability to manufacture your design in-house and providing a cost-effective and streamlined outcome.

Not sure the best material to use for the manufacture of your equipment? Australis can help. We have the capability to manufacture to our designs in the following materials:

- 304 Stainless Steel

- 316 Stainless Steel

- Mild Steel including painted, powder coated or galvanised

- Aluminium profile

With the in-house capability to manufacture a wide diversity of materials, Australis can advise you on the best options to achieve the structural integrity, longevity and budgetary requirements to suit your designs.

Difficult manufacturing environment?

Australis are experts in designing and manufacturing special purpose machinery to accommodate the requirements of the most demanding manufacturing environments. We can manufacture your equipment to ensure it complies with all relevant Australian or International standards and will provide years of reliable service. We specialise in providing manufactured solutions for:

- Wash down

- Dairy

- Fresh meat and poultry

- Anti-bacterial

- Sub-zero freezers

- Explosion proof

- Anti-static

- Solvents

- Acids and alkalis

- Toxic/ hazardous substances

- Precious metals and coins

Click on the case study below to view

Find out more by reading the following Case Studies of some of our Customised Materials Handling Equipment solutions:

AFS – Conveyor system for architectural wall panels

Orica – Hexachloro Benzine waste repackaging system

Alto Manufacturing – Customised cup conveying system with accumulator

The following video demonstrates a fully customised solution at the Royal Australian Mint, Canberra and includes fully customised machinery such as our Vision Counting System

While it might not be as exciting as the Mint project, the following is a customised train wheel tipping machine that we manufactured for UGL – Rail:

Click here or on the brochure image to view more information on our Materials Handling Solutions, including fully customised, special purpose equipment

Click here or on the brochure image to view more information on our Materials Handling Solutions, including fully customised, special purpose equipment RELATED PRODUCTS

PREVIOUS CLIENTS