Vision Counting System

Vision System for Counting Coins

Coins and banknotes are a precious and valuable commodity, so if your business revolves around the production, packaging or storage of coins or banknotes, you want a partner who has the experience to develop and integrate solutions that will meet your security, safety, audit and quality objectives. Australis Engineering have an enviable track record in providing solutions for clients in the Coin Minting and handling industry. Whether you need an entire turnkey solution to revitalise your coin manufacturing facility, or simply need to upgrade your coin packaging, storage or handling systems, Australis has the experience to design, manufacture and install a system that will meet your requirements.

World’s First Vision Counting System for Coin Blanks – designed by Australis Engineering

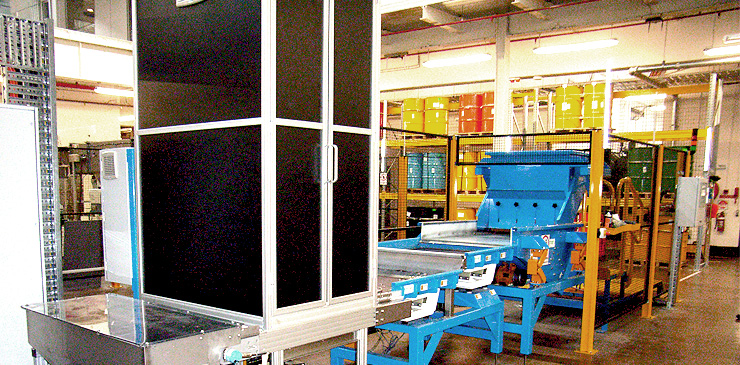

As part of the Royal Australian Mint’s (RAM) modernisation program for their circulating coin production facility, RAM sought to upgrade its circulating coin blank handling and finished coin warehousing with a state of the art system incorporating leading edge technology including, increased product security; providing high levels of process automation and process management and better knowledge of production rates for each coin denomination. Key to these outcomes was the World’s first coin Vision Counting System (VCS), designed and manufactured by Australis Engineering.

Vision Counting System for Coin Blanks

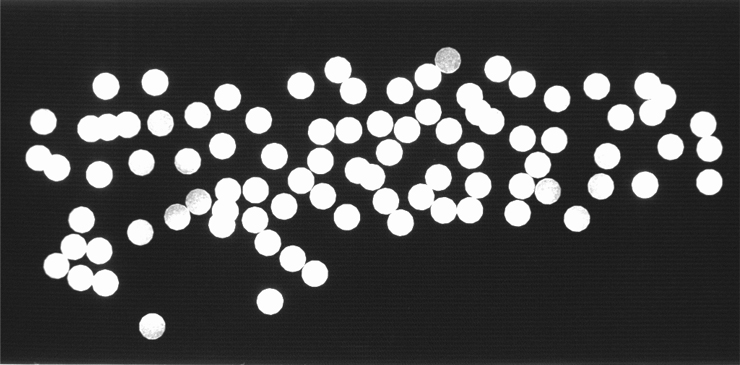

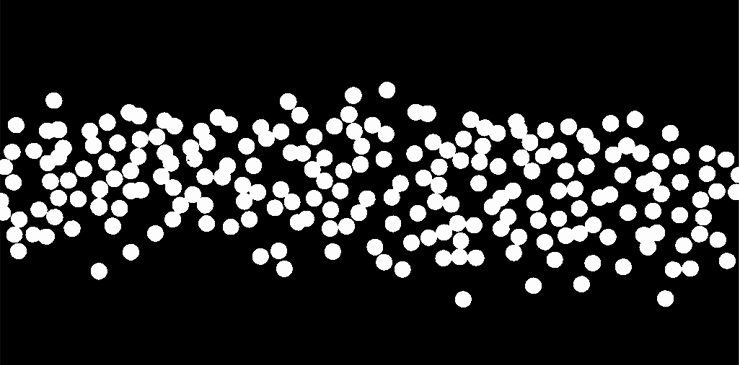

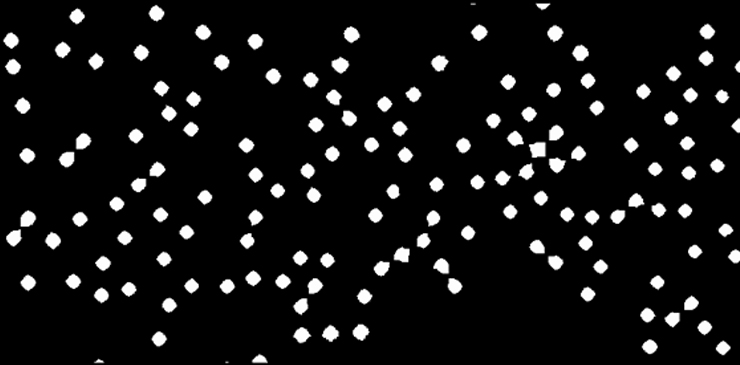

Our World’s first, Vision Counting System (VCS) for coins is a high-speed coin blank counter that counts coin blanks as they are dumped into the coin production line via 44 gallon drums. The VCS therefore counts the coin blanks in a mass flow situation, allowing for elevated through put speeds and high throughput counting of up to 22,000 coins per minute. The system is designed to be virtually touch free so there is little chance of jams or blockages, while also adding to security outcomes and results in a highly reliable system achieving over 99.9% accuracy in production (depending on coin blank denomination).

High speed cameras and sophisticated software that was developed by Australis’ Automation Engineers filters and counts the coin blanks in this mass flow environment and differentiates coin blanks (even those that are overlapping each other), to produce a very accurate count of the coin blank input to the coin manufacturing process. This has enabled better forecasting of coin production and warehousing requirements and has also allowed for better management of the coin blank supply chain.

Other Applications

With adaptation, the VCS has potential in for other small, high value products that need to be counted in a mass-flow situation. This might include other coin handling environments and in the pharmaceutical industry for tablet production facilities.

Contact us to further discuss the application of this technology in your production plant.

Contact UsClick on the case study below to view

Find out more by reading the case study of our Materials Handling and Warehousing Solution at the Royal Australian Mint, Canberra including information on the VCS.

Royal Australian Mint, Materials Handling and Warehousing Solution

Want to know more about our Award Winning Circulation Coin Manufacturing solution at the Royal Australian Mint, Canberra? Watch a short video of the system in operation below which also shows the VCS in operation (scroll to the 1.50 – 2.23 mark of the video to see the VCS process) .

Click here or on the brochure image to view more information on our Materials Handling Solutions.

Click here or on the brochure image to view more information on our Materials Handling Solutions.

RELATED PRODUCTS

PREVIOUS CLIENTS